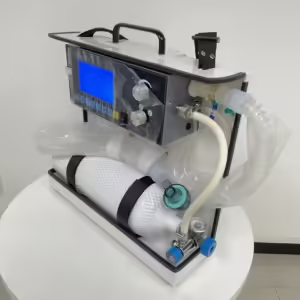

Autoclave Unit

An autoclave unit, often simply referred to as an autoclave, is a device used to sterilize equipment and supplies by subjecting them to high-pressure saturated steam at high temperatures. It is widely used in medical, dental, and laboratory settings to ensure that instruments and other items are free from any viable microorganisms, including bacteria, viruses, fungi, and spores.

Description

Autoclave Unit

An autoclave unit, often simply referred to as an autoclave, is a device used to sterilize equipment and supplies by subjecting them to high-pressure saturated steam at high temperatures. It is widely used in medical, dental, and laboratory settings to ensure that instruments and other items are free from any viable microorganisms, including bacteria, viruses, fungi, and spores.

Components

- Chamber: The main container where items to be sterilized are placed.

- Steam Generator: Produces the steam necessary for the sterilization process.

- Control System: Manages the parameters of the sterilization cycle such as temperature, pressure, and time.

- Pressure and Temperature Gauges: Monitor the conditions inside the chamber.

- Door or Lid: Seals the chamber to maintain pressure and temperature.

- Safety Valves: Ensure the unit operates safely by releasing excess pressure.

Operation

- Loading: Instruments and materials to be sterilized are placed inside the chamber.

- Sealing: The door or lid is securely closed to ensure a tight seal.

- Heating and Pressurizing: Steam is generated and introduced into the chamber, increasing both temperature and pressure.

- Sterilization Cycle: The contents are subjected to a specified combination of high temperature (typically 121-134°C or 250-273°F) and pressure (typically 15-30 psi) for a set duration.

- Exhaust and Drying: Steam is vented out, and the contents are dried, either through additional heating or by vacuum.

Types

- Gravity Displacement Autoclave: Steam displaces air in the chamber by gravity, typically used for less dense materials.

- Pre-Vacuum Autoclave: Air is removed before steam is introduced, ensuring more efficient and uniform penetration of steam, ideal for porous materials.

- High-Speed Autoclave: Designed for faster sterilization cycles, suitable for urgent needs.

- Portable Autoclave: Smaller, more mobile units for use in settings with limited space.

Applications

- Medical and Dental Instruments: Sterilization of surgical tools, dental handpieces, and other reusable items.

- Laboratory Equipment: Sterilization of glassware, culture media, and lab instruments.

- Pharmaceuticals: Sterilization of products and containers.

- Tattoo and Piercing Studios: Sterilization of needles and other equipment.

Importance

- Infection Control: Ensures that all instruments are free from pathogens, preventing the spread of infections.

- Compliance: Meets regulatory standards for sterilization in healthcare and laboratory settings.

- Efficiency: Provides a reliable and fast method of sterilization.

Maintenance

Regular maintenance is crucial for effective operation, including:

- Routine Cleaning: Regularly clean the chamber and other components.

- Inspection: Regularly check seals, valves, and gauges.

- Calibration: Ensure the control system is accurately set to the required parameters.

In summary, an autoclave unit is a vital piece of equipment in various settings that require sterile instruments and materials. It operates by using high-pressure steam to achieve effective sterilization, ensuring safety and compliance with health standards.

Reviews

There are no reviews yet.